Highwall Pumps

The Highwall Pump is designed to have the main frame / power pack situated on top

of the highwall edge, with the wet-end lowered over the pit wall and into the water

accumulation on the pit floor.

The advantages of this pump format over conventional pit type pumps are:

- Quick mobilization and demobilization with minimum labour requirements.

- The pump delivery hose is positioned in place with the wet-end.

- The bulk of the pump unit remains clear of mining operations.

- Eliminates the need for Pump Crew to work in the pit near the Highwall.

- Access to water accumulating in a pit being developed by dragline operation is achieved without hindering the operations.

By incorporating a second (booster) pump unit to the Highwall Pump, performance is improved to 100L/sec @ 200m head TDH. The booster pump is hard plumbed into the outlet of the primary pump, allowing for simple and efficient transferring of water at high head.

By utilizing a single pump unit to lift to 200m, operating of a single engine, all complexities of setting up staging pumps, including manoeuvring of a second unit, connecting pipe work, balancing performance, and monitoring both units is eliminated.

This unit is designed to have the main frame / power pack situated adjacent to the highwall edge, with the wet-end lowered over the pit wall and into the water accumulation on the pit floor. The advantages of this pump format over conventional pit type pumps are:

This unit is designed to have the main frame / power pack situated adjacent to the highwall edge, with the wet-end lowered over the pit wall and into the water accumulation on the pit floor. The advantages of this pump format over conventional pit type pumps are:

- Quick mobilisation and demobilisation with minimum labour requirements

- The pump delivery hose is positioned in place with the wet-end

- The bulk of the pump unit remains clear of mining operations

- The unit is clear of muddy conditions, and easily accessed for service

- Access to water accumulating in a pit being developed by dragline operation is achieved without hindering operations

By incorporating a second (booster) pump unit to the Highwall Pump, performance is improved to 200L/sec @ 200m head TDH. The booster pump is hard plumbed into the outlet of the primary pump, allowing for simple and efficient transferring of water at high head.

By utilising a single pump unit to lift to 200m, operating of a single engine, all complexities of setting up staging pumps, including manoeuvring of a second unit, connecting pipe work, balancing performance, and monitoring both units is eliminated.

Water Pump Primary

| Pump | Hyd Driven – Hard Metal (28{fc62a668ba4fc924e3659cb952537edb37ef7e0fa689fb036a45ca818e77ff15} chrome) Slurry Pump |

| Suction | Fabricated screened suction – galvanized – footvalve not fitted |

| Drive | 355cc fixed displacement axial piston motor |

| Speed | Max 1800 R/M |

| Arrangement | Motor drives pump shaft through a coupling supported by taperedroller bearings in a sealed housing. Bearings are lubed by case oil. Mechanical seal prevents leakage. |

| Pump Performance | 200 L/s @ 100m head TDH unworn pump, clean water @ 1700rpm pump speed. |

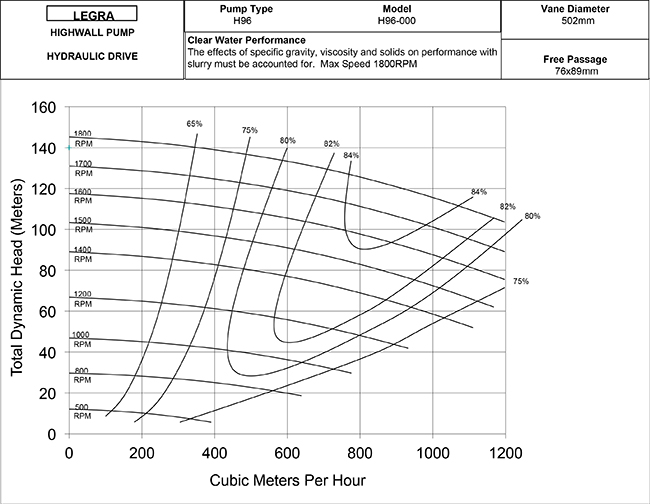

| Pump Curve | Legra 9000 Curve H96-200 |

Water Pump Booster

| Pump | Hyd Driven – Hard Metal (28{fc62a668ba4fc924e3659cb952537edb37ef7e0fa689fb036a45ca818e77ff15} chrome) Slurry Pump |

| Suction | 10” drop pipe from reel |

| Drive | 355cc fixed displacement axial piston motor |

| Speed | Max 1800 R/M |

| Arrangement | Motor drives pump shaft through a coupling supported by tapered roller bearings in a sealed housing. Bearings are lubed by case oil. Mechanical seal prevents leakage. |

| Pump Performance | 200 L/s @ 100m head TDH unworn pump, clean water @ 1700rpm pump speed |

Wetend Positioning Support

| Wheels | 2 x 750 x 16” wheels fitted to 1550mm x 65mm SHS axle are mounted across the wet-end, and assist in positioning the wet-end during lifting or lowering. |

| Support bracket | Hydraulically (ram) operated support constructed from RHS and Flat, acts as support for the wet-end during travelling, and hose positioning during lowering. |

Water Conduit

| Length / Type | 120m of 250 O.D. Poly standard supply. |

| Hydraulic Hoses | 2" High pressure - Multi Spiral - pressure hose to motor drive. 2" Medium pressure - Double Braid - hose return line. |

Hose Reel

| Size | 3625 dia drum. 4500 dia rim. Capacity to 120m of 250 OD Poly. |

| Construction | 6-150x50x4 R.H.S spokes each side welded to hub flange and rim. 5mm M.S. plate drum. 35x35x2.5 HT SHS rims. |

| Reel Method of Support | Hydraulic Gland and Water Discharge Gland |

| Water Discharge | 300 NB Table E flange 300mm from ground level. 40NB Ball valve fitted. |

Main Frame Type

Heavy skid base – fully weld fabricated unit construction comprised of UB side runners (with wear plate). Heavy R.H.S. cross members, supporting the R.H.S. reel mounting frame. Heavy front tube with push pads, engine mounting, engine canopy, front bars for engine protection, fuel tank mountings, oil reservoir mountings, safety mesh mountings, and tow chain.

| Dimension | Overall – 16.335m x 2.55m x 5.2m High |

| Weight | Approx 20 Tonne |

| Skid Runners | 360UB56 |

| Wear Plate | 20mm Bisalloy 500 - 250mm wide |

| Cross Members | 250x150x6 R.H.S |

| Reel Frame Uprights | 2-250x150x6 & 2 150x150x6mm |

| Reel Frame | 200x100x6 R.H.S |

| Extension Beams | 75x75x4 R.H.S & 127 x 75 x 4 R.H.S. |

| Extension Bracing | 65x65x3 B.H.S and 50x50x3 S.H.S AS1163 C450LO Duragal |

| Push Pads | 250x150x9 R.H.S capped w/-20 ms plate |

| Engine Mounting | 150x100x12 Angle Iron |

| Engine Canopy | Formed 3mm flat mild steel |

| Engine Protection | 200.N.B. sched 40 pipe mounted on 360 U.B. uprights |

| Towing Chains | 2 of 3.4m long of 20mm Hercalory with 260x140x38 tow-ring link (inside dimension). Attached front end only. |

| Hose Roller Guide System | 6 Shaped roller, bearing mounted in two 12mm MS plate chain driven from four hydraulic motors, in series with the reel motor. |

Hydraulic System

| Hydraulic Pump | 355cc pressure comp flow control piston pump. Flex coupled to engine flywheel |

| Operating Speed | 1800 R/M |

| Flow at Duty | 639 L/M |

| Max Pressure Rating | 4060 P.S.I. (280 bar) |

| Operating Pressure | 3625 P.S.I. (250 bar) |

| Main Relief Valve | 1" high pressure spike relief - catridge type |

| Twin Port Rotating Gland | Legra type HD for 1½" fittings - H25-000 |

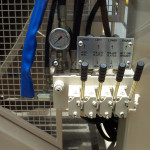

| Auxiliary Control Valve | 4 Bank load sense on reel, slew, and tilt and pump support |

| Reel Drive | Hydraulic motor driving via a 30:1 reduction box & 5:1 x 2” chain reduction |

| Hose Drive Motor | 4 of geroler hydraulic motors |

| Load Check Valve | Double acting overcentre valves and hydraulic brake coupled to the reel motor |

| High Pressure Hose System | 2" dia. multi spiral high pressure |

| Return Line | 2" dia. double braid low pressure. |

| Hoses-Auxiliary System | ½" or 5/8" dia. Double braid medium pressure |

| Reservoir | 800Lts mild steel fabricated, fitted with oil outlet, oil return, level temperature sight glass, high and low level oil protection, drain outlet. Sand blasted internally. |

| Auxiliary Hyd Reservoir | 100Lts Auxiliary tank fitted to main frame, pumped into main reservoir via the hydraulic filters, and incorporating an electrically operated diaphragm pump. Used for top up of main reservoir. |

| Return Line Filter | 2 of 1½" dual element cartridge type. Watchdog pressure gauge fitted, and shuts down engine should elements become clogged. |

| Oil | Mineral Oil of ISO viscosity grade 22 |

Power Unit

| Engine | C27 Cat. Turbo charged, after cooled V12 cyl. |

| Electrical/Watchdog | 24V Electric’s, 2 work lights fitted, battery isolator fitted. Engine will be monitored by OEM supplied engine management system all other perameters will be monitored by PLC controlled board with digital fault display. |

| Fuel Cell | 3000Lts capacity with Wiggins fittings. Weld fabricated mild steel mounted on water discharge side of frame. Drain plug fitted. Blasted internally. |

| Fuel Lines | 12mm hydraulic hose on supply line. 12mm hydraulic hose return line. |

Painting

All frame work blasted to A.S. class 2½, primed and painted Interfine 629 White.

Functions

| Engine at 1000RPM to 1200 RPM | Auxiliary control valve functions. 4 functions - Wet-end lift/ lower Roller Plate Slew for aligning the hose to reel during reclaim Roller Plate traverse for assisting hose and wet-end entry to pit Wet-End Support Bracket supports wet-end and guides hose on initial wall contact |

| Engine up to 1800 RPM | Operation of pump functions. Booster Pump speed is controlled with PLC. PLC maintains speed of booster pump to ensure a set pressure is maintained at booster pump suction. |

The foregoing specification is correct at time of publication however, LEGRA reserve the right

to amend the specification as required in keeping with market development.

This unit is designed to have the main frame / power pack situated adjacent to the highwall edge, with the wet-end lowered over the pit wall and into the water accumulation on the pit floor. The advantages of this pump format over conventional pit type pumps are:

This unit is designed to have the main frame / power pack situated adjacent to the highwall edge, with the wet-end lowered over the pit wall and into the water accumulation on the pit floor. The advantages of this pump format over conventional pit type pumps are:

- Quick mobilization and demobilization with minimum labour requirements

- The pump delivery hose is positioned in place with the wet-end

- The bulk of the pump unit remains clear of mining operations

- The unit is clear of muddy conditions, and easily accessed for service

- Access to water accumulating in a pit being developed by dragline operation is achieved without hindering operations

Water Pump

| Pump | Hyd Driven – Hard Metal (28{fc62a668ba4fc924e3659cb952537edb37ef7e0fa689fb036a45ca818e77ff15} chrome) Slurry Pump |

| Suction | Fabricated screened suction – galvanized – footvalve not fitted |

| Drive | 355cc fixed displacement axial piston motor |

| Speed | Max 1800 R/M |

| Arrangement | Motor drives pump shaft through a coupling supported by tapered roller bearings in a sealed housing. Bearings are lubed by case oil. Mechanical seal prevents leakage. |

| Pump Performance | 200 L/s @ 100m head TDH unworn pump, clean water @ 1700rpm pump speed. |

| Pump Curve | GIW Curve E 4D-92 |

Wetend Positioning Support

| Wheels | 2 x 750 x 16” wheels fitted to 1550mm x 65mm SHS axle are mounted across the wet-end, and assist in positioning the wet-end during lifting or lowering. |

| Support bracket | Hydraulically (ram) operated support constructed from RHS and Flat, acts as support for the wet-end during travelling, and hose positioning during lowering. |

Water Conduit

| Length / Type | 120m of 250 O.D. Poly standard supply. |

| Hydraulic Hoses | 2" High pressure - Multi Spiral - pressure hose to motor drive. 2" Medium pressure - Double Braid - hose return line. |

Hose Reel

| Size | 3625 dia drum. 4500 dia rim. Capacity to 120m of 250 OD Poly. |

| Construction | 6-150x50x4 R.H.S spokes each side welded to hub flange and rim. 5mm M.S. plate drum. 35x35x2.5 HT SHS rims. |

| Reel Method of Support | Hydraulic Gland and Water Discharge Gland |

| Water Discharge | 300 NB Table E flange 300mm from ground level. 40NB Ball valve fitted. |

Main Frame Type

Heavy skid base – fully weld fabricated unit construction comprised of UB side runners (with wear plate). Heavy R.H.S. cross members, supporting the R.H.S. reel mounting frame. Heavy front tube with push pads, engine mounting, engine canopy, front bars for engine protection, fuel tank mountings, oil reservoir mountings, safety mesh mountings, and tow chain.

| Dimension | Overall – 16.335m x 2.55m x 5.2m High Ground contact 7300mm. Mainframe 7900mm x 2400mm. |

| Weight | Approx 20 Tonne |

| Skid Runners | 360UB56 |

| Wear Plate | 20mm Bisalloy 500 - 250mm wide |

| Cross Members | 250x150x6 R.H.S |

| Reel Frame Uprights | 2-250x150x6 & 2 150x150x6mm |

| Reel Frame | 200x100x6 R.H.S |

| Extension Beams | 75x75x4 R.H.S & 127 x 75 x 4 R.H.S. |

| Extension Bracing | 65x65x3 B.H.S and 50x50x3 S.H.S AS1163 C450LO Duragal |

| Push Pads | 250x150x9 R.H.S capped w/-20 ms plate |

| Engine Mounting | 150x100x12 Angle Iron |

| Engine Canopy | Formed 3mm flat mild steel |

| Engine Protection | 200.N.B. sched 40 pipe mounted on 360 U.B. uprights |

| Towing Chains | 2 of 3.4m long of 20mm Hercalory with 260x140x38 tow-ring link (inside dimension). Attached front end only. |

| Hose Roller Guide System | 6 Shaped roller, bearing mounted in two 12mm MS plate chain driven from four hydraulic motors, in series with the reel motor. |

Hydraulic System

| Hydraulic Pump | 355cc pressure comp flow control piston pump. Flex coupled to engine flywheel |

| Operating Speed | 1800 R/M |

| Flow at Duty | 639 L/M |

| Max Pressure Rating | 4060 P.S.I. (280 bar) |

| Operating Pressure | 3625 P.S.I. (250 bar) |

| Main Relief Valve | 1" high pressure spike relief - catridge type |

| Twin Port Rotating Gland | Legra type HD for 1½" fittings - H25-000 |

| Auxiliary Control Valve | 4 Bank load sense on reel, slew, and tilt and pump support |

| Reel Drive | Hydraulic motor driving via a 30:1 reduction box & 5:1 x 2” chain reduction |

| Hose Drive Motor | 4 of geroler hydraulic motors |

| Load Check Valve | Double acting overcentre valves and hydraulic brake coupled to the reel motor |

| High Pressure Hose System | 2" dia. multi spiral high pressure |

| Return Line | 2" dia. double braid low pressure. |

| Hoses-Auxiliary System | ½" or 5/8" dia. Double braid medium pressure |

| Reservoir | 800Lts mild steel fabricated, fitted with oil outlet, oil return, level temperature sight glass, high and low level oil protection, drain outlet. Sand blasted internally. |

| Auxiliary Hyd Reservoir | 100Lts Auxiliary tank fitted to main frame, pumped into main reservoir via the hydraulic filters, and incorporating an electrically operated diaphragm pump. Used for top up of main reservoir. |

| Return Line Filter | 1 of 3" cartridge type. Watchdog pressure gauge fitted, and shuts down engine should elements become clogged. |

| Oil | Mineral Oil of ISO viscosity grade 22 |

Power Unit

| Engine | Cummins QSX15 or C15 Caterpillar. Turbo charged, after cooled 6 cyl. |

| Electrical/Watchdog | 24V Electric’s, 2 work lights fitted, battery isolator fitted.Engine will be monitored by OEM supplied engine management system all other perameters will be monitored by PLC controlled board with digital fault display. |

| Fuel Cell | 2000Lts capacity with Wiggins fittings. Weld fabricated mild steel mounted on water discharge side of frame. Drain plug fitted. Blasted internally. |

| Fuel Lines | 10mm hydraulic hose on supply line. 10mm hydraulic hose return line. |

Painting

All frame work blasted to A.S. class 2½, primed and painted Interfine 629 White.

Functions

| Engine at 1000RPM to 1200 RPM | Auxiliary control valve functions. 4 functions - Wet-end lift/ lower Roller Plate Slew for aligning the hose to reel during reclaim Roller Plate traverse for assisting hose and wet-end entry to pit Wet-End Support Bracket supports wet-end and guides hose on initial wall contact |

| Engine up to 1800 RPM | Operation of pump function |

The foregoing specification is correct at time of publication however, LEGRA reserve the right

to amend the specification as required in keeping with market development.

This unit is designed to have the main frame / power pack situated adjacent to the highwall edge, with the wet-end lowered over the pit wall and into the water accumulation on the pit floor. The advantages of this pump format over conventional pit type pumps are:

This unit is designed to have the main frame / power pack situated adjacent to the highwall edge, with the wet-end lowered over the pit wall and into the water accumulation on the pit floor. The advantages of this pump format over conventional pit type pumps are:

- Quick mobilization and demobilization with minimum labour requirements

- The pump delivery hose is positioned in place with the wet-end

- The bulk of the pump unit remains clear of mining operations

- Eliminates the need for Pump Crew to work in the pit near the Highwall

- Access to water accumulating in a pit being developed by dragline operation is achieved without hindering the operations

- Able to operate and be serviced in all weather conditions

By incorporating a second (booster) pump unit to the Highwall Pump, performance is improved to 100L/sec @ 200m head TDH. The booster pump is hard plumbed into the outlet of the primary pump, allowing for simple and efficient transferring of water at high head.

By utilizing a single pump unit to lift to 200m, operating of a single engine, all complexities of setting up staging pumps, including manoeuvring of a second unit, connecting pipe work, balancing performance, and monitoring both units is eliminated.

Water Pump Primary

| Pump | Cast Iron Volute. 28{fc62a668ba4fc924e3659cb952537edb37ef7e0fa689fb036a45ca818e77ff15} Chrome Impeller and Suction Plate |

| Suction | Fabricated screened suction – Galvanized. No footvalve fitted. |

| Drive | 160cc fixed displacement axial piston motor |

| Speed | Max 2200 R/M |

| Arrangement | Motor drives pump shaft through a coupling supported by tapered roller bearings in a sealed housing. Bearings are lubricated by case oil. Mechanical seal prevents leakage. |

| Pump Performance | 100 L/s @ 100m head unworn pump, clean water @ 2150rpm pump speed |

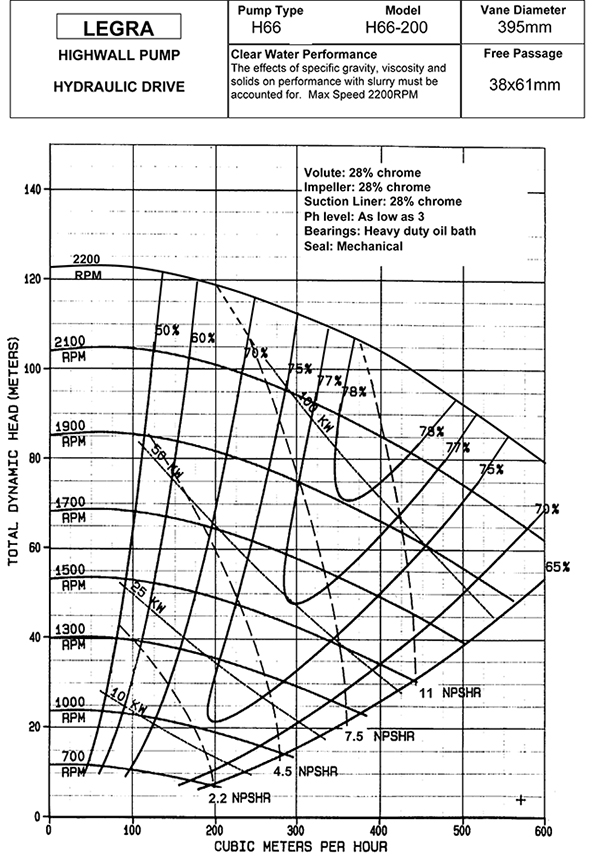

| Pump Curve | Impeller clearance is adjusted by bolt/lock nut adjustment |

Water Pump Booster

| Pump | Cast Iron Volute. 28{fc62a668ba4fc924e3659cb952537edb37ef7e0fa689fb036a45ca818e77ff15} Chrome Impeller and Suction Plate. |

| Suction | 8” drop pipe from reel |

| Drive | 160cc fixed displacement axial piston motor |

| Speed | Max 2200 R/M |

| Arrangement | Motor drives pump shaft through a coupling supported by tapered roller bearings in a sealed housing. Bearings are lubricated by case oil. Mechanical seal prevents leakage. |

| Pump Performance | 100 L/s @ 100m head unworn pump, clean water @ 2150rpm pump speed |

| Pump Curve | Impeller clearance is adjusted by bolt/lock nut adjustment. |

Wetend Positioning Support

| Wheels | 2 x 750 x 16” wheels fitted to 1550mm x 40mm axle are mounted across the wet-end, and assist in positioning the wet-end during lifting or lowering. |

| Support bracket | Hydraulically (ram) operated, acts as support for the wet-end during travelling, and hose positioning during lowering. |

Water Conduit

| Length / Type | 125m of 200f Poly standard supply. |

| Hydraulic Hoses | 1-1½" High pressure - Multi Spiral - pressure hose to motor drive. 1-1½" Medium pressure - Double Braid - hose return line. |

Hose Reel

| Size | 2900f drum. 3700f rim.. Capacity to 125m of 200f Poly. |

| Construction | R.H.S spokes each side welded to hub flange and rim. 5mm M.S. plate drum. |

| Reel Method of Support | Hydraulic Gland and Water Discharge Gland |

| Water Discharge | 200NB Table E flange 300mm from ground level. 40NB Ball valve fitted. |

Main Frame Type

Heavy skid base – fully weld fabricated unit construction comprised of UB side runners (with wear plate). Heavy R.H.S. cross members, supporting the R.H.S. reel mounting frame. Heavy front tube with push pads, engine mounting, engine canopy, front bars for engine protection, fuel tank mountings, oil reservoir mountings, safety mesh mountings, and tow chain.

| Dimension | Overall – 13500mm x 2850mm x 4059mm Ground contact 6700mm x 2830mm. Mainframe 7300mm x 2700mm. |

| Dry Weight | 14 tonne |

| Skid Runners | 360UB56. Fitted with 20mm Bisalloy 500 Wear Plate. |

| Jib Extension Beams | 75x75x3 R.H.S & 127 x 75 x 3 R.H.S |

| Extension Bracing | 65x65x3 R.H.S and 50x50x3 S.H |

| Push Pads | 250x150x9 R.H.S capped w/-20 ms plate. |

| Engine Mounting | 150x100x12 Angle Iron |

| Engine Canopy | Formed 3mm flat mild steel |

| Engine Protection | 200.N.B. sched 40 pipe mounted on 360 U.B. uprights |

| Towing Chains | 2 of 3.4m long of 20mm Hercalloy with 260x140x38 tow-ring link at front. |

Hydraulic System

| Hydraulic Pump | 2 of Rexroth A11VLO190 pressure compensated flow control piston pumps. In Tandem. Coupled to engine flywheel. |

| Operating Speed | 1800 R/M |

| Flow at Duty | 340 L/m. per pump |

| Max Pressure Rating | 4060 P.S.I. (280 bar) |

| Operating Pressure | 3625 P.S.I. (250 bar) |

| Auxiliary Control Valve | 4 Bank load sense on reel, slew, and tilt and pump support. |

| Reel Drive | Hydraulic motor driving via a 30:1 reduction box & 5:1 x 2” chain reduction. |

| Load Check Valve | Double acting overcentre valves and hydraulic brake coupled to the reel motor. |

| High Pressure Hose System | 1½"f. multi spiral high pressure. |

| Return Line | 1½"f double braid low pressure. |

| Hoses-Auxiliary System | ½" or 5/8"f double braid medium pressure. |

| Reservoir | 800Lts mild steel fabricated, fitted with oil outlet, oil return. |

| Auxiliary Hyd Reservoir | 100Lts Auxiliary tank fitted to main frame, pumped into main reservoir via the hydraulic filters, and incorporating a 12v transfer pump. |

| Return Line Filter | 2 of 1½" dual element cartridge type. 3 Micron Nominal Filtration |

| Oil | Mineral Oil of ISO viscosity grade 22 |

Power Unit

| Engine | Cat (C15) or Cummins (QSX15). Turbo charged, after cooled 6 cylinders. Other options available on request |

| Engine Management | Programmable Logic Control (PLC) controls and monitors all shut-down functions. Protection on engine oil pressure, radiator level, engine temperature, high and low levels of hydraulic oil, high and low hydraulic pressure, high and low water pressure at Booster Pump Suction, and hydraulic filter pressure. First out indicator identifies source of engine shutdown PLC operates speed of Booster Pump to maintain synch with Primary Pump. |

| Fuel Cell | 2200Lts capacity with Wiggins fittings. |

Painting

All frame work blasted to A.S. class 2½, primed and painted Interfine 629 White.

Functions

| Engine at 800RPM to 1000 RPM | Auxiliary control valve functions. 4 functions - Wet-end lift/ lower Roller Plate Slew for aligning the hose to reel during reclaim Roller Plate traverse for assisting hose and wet-end entry to pit Wet-End Support Bracket supports wet-end and guides hose on initial wall contact |

| Engine up to 1800 RPM | Operation of pump functions. Booster Pump speed is controlled with PLC. PLC maintains speed of booster pump to ensure a set pressure is maintained at booster pump suction. |

The foregoing specification is correct at time of publication however, LEGRA reserve the right to amend the specification as required in keeping with market development.

This unit is designed to have the main frame / power pack situated adjacent to the highwall edge, with the wet-end lowered over the pit wall and into the water accumulation on the pit floor. The advantages of this pump format over conventional pit type pumps are:

This unit is designed to have the main frame / power pack situated adjacent to the highwall edge, with the wet-end lowered over the pit wall and into the water accumulation on the pit floor. The advantages of this pump format over conventional pit type pumps are:

- Quick mobilization and demobilization with minimum labour requirements

- The pump delivery hose is positioned in place with the wet-end

- The bulk of the pump unit remains clear of mining operations

- Eliminates the need for Pump Crew to work in the pit near the Highwall

- Access to water accumulating in a pit being developed by dragline operation is achieved without hindering the operations

- Able to operate and be serviced in all weather conditions

Capacity to 100L/sec @ 100M Head

Water Pump

| Pump | Cast Iron Volute. 28{fc62a668ba4fc924e3659cb952537edb37ef7e0fa689fb036a45ca818e77ff15} Chrome Impeller and Suction Plate |

| Suction | Fabricated screened suction – Galvanized. No footvalve fitted. |

| Drive | 160cc fixed displacement axial piston motor |

| Speed | Max 2200 R/M |

| Arrangement | Motor drives pump shaft through a coupling supported by tapered roller bearings in a sealed housing. Bearings are lubricated by case oil. Mechanical seal prevents leakage. |

| Pump Performance | 100 L/s @ 100m head unworn pump, clean water @ 2150rpm pump speed |

| Pump Curve | Impeller clearance is adjusted by bolt/lock nut adjustment |

Wetend Positioning Support

| Wheels | 2 x 750 x 16” wheels fitted to 1550mm x 40mm axle are mounted across the wet-end, and assist in positioning the wet-end during lifting or lowering. |

| Support bracket | Hydraulically (ram) operated, acts as support for the wet-end during travelling, and hose positioning during lowering. |

Water Conduit

| Length / Type | 125m of 200f Poly standard supply. |

| Hydraulic Hoses | 1-1½" High pressure - Multi Spiral - pressure hose to motor drive. 1-1½" Medium pressure - Double Braid - hose return line. |

Hose Reel

| Size | 2900f drum. 3700f rim.. Capacity to 125m of 200f Poly. |

| Construction | R.H.S spokes each side welded to hub flange and rim. 5mm M.S. plate drum. |

| Reel Method of Support | Hydraulic Gland and Water Discharge Gland |

| Water Discharge | 200NB Table E flange 300mm from ground level. 40NB Ball valve fitted. |

Main Frame Type

Heavy skid base – fully weld fabricated unit construction comprised of UB side runners (with wear plate). Heavy R.H.S. cross members, supporting the R.H.S. reel mounting frame. Heavy front tube with push pads, engine mounting, engine canopy, front bars for engine protection, fuel tank mountings, oil reservoir mountings, safety mesh mountings, and tow chain.

| Dimension | Overall – 12635mm x 2550mm x 4059mm Ground contact 6400mm x 2628mm. Mainframe 7400mm x 2400mm. |

| Dry Weight | 12.3 tonne |

| Skid Runners | 360UB56. Fitted with 20mm Bisalloy 500 Wear Plate. |

| Jib Extension Beams | 75x75x3 R.H.S & 127 x 75 x 3 R.H.S. |

| Extension Bracing | 65x65x3 R.H.S and 50x50x3 S.H.S. |

| Push Pads | 250x150x9 R.H.S capped w/-20 ms plate. |

| Engine Mounting | 150x100x12 Angle Iron |

| Engine Canopy | Formed 3mm flat mild steel |

| Engine Protection | 200.N.B. sched 40 pipe mounted on 360 U.B. uprights |

| Towing Chains | 2 of 3.4m long of 20mm Hercalloy with 260x140x38 tow-ring link at front. |

Hydraulic System

| Hydraulic Pump | Rexroth A11VLO190 pressure compensated flow control piston pump. Coupled to engine flywheel. |

| Operating Speed | 2000 R/M |

| Flow at Duty | 340 L/m. per pump |

| Max Pressure Rating | 4060 P.S.I. (280 bar) |

| Operating Pressure | 3625 P.S.I. (250 bar) |

| Auxiliary Control Valve | 4 Bank load sense on reel, slew, and tilt and pump support. |

| Reel Drive | Hydraulic motor driving via a 30:1 reduction box & 5:1 x 2” chain reduction. |

| Load Check Valve | Double acting overcentre valves and hydraulic brake coupled to the reel motor. |

| High Pressure Hose System | 1½"f. multi spiral high pressure. |

| Return Line | 1½"f double braid low pressure. |

| Hoses-Auxiliary System | ½" or 5/8"f double braid medium pressure. |

| Reservoir | 800Lts mild steel fabricated, fitted with oil outlet, oil return. |

| Auxiliary Hyd Reservoir | 100Lts Auxiliary tank fitted to main frame, pumped into main reservoir via the hydraulic filters, and incorporating a 12v transfer pump. |

| Return Line Filter | 2 of 1½" dual element cartridge type. 3 Micron Nominal Filtration |

| Oil | Mineral Oil of ISO viscosity grade 22 |

Power Unit

| Engine | Cat (C15) or Cummins (QSX15). Turbo charged, after cooled 6 cylinders. Other options available on request |

| Engine Management | Programmable Logic Control (PLC) controls and monitors all shut-down functions. Protection on engine oil pressure, radiator level, engine temperature, high and low levels of hydraulic oil, high and low hydraulic pressure, and hydraulic filter pressure. Display indicator identifies source of engine shutdown. |

| Fuel Cell | 2200Lts capacity with Wiggins fittings |

Painting

All frame work blasted to A.S. class 2½, primed and painted Interfine 629 White.

Functions

| Engine at 800RPM to 1000 RPM | Auxiliary control valve functions. 4 functions - Wet-end lift/ lower Roller Plate Slew for aligning the hose to reel during reclaim Roller Plate traverse for assisting hose and wet-end entry to pit Wet-End Support Bracket supports wet-end and guides hose on initial wall contact |

| Engine up to 1800 RPM | Operation of pump functions. Booster Pump speed is controlled with PLC. PLC maintains speed of booster pump to ensure a set pressure is maintained at booster pump suction. |

The foregoing specification is correct at time of publication however, LEGRA reserve the right to amend the specification as required in keeping with market development.

This unit is designed to have the main frame / power pack situated adjacent to the highwall edge, with the wet-end lowered over the pit wall and into the water accumulation on the pit floor. The advantages of this pump format over conventional pit type pumps are:

This unit is designed to have the main frame / power pack situated adjacent to the highwall edge, with the wet-end lowered over the pit wall and into the water accumulation on the pit floor. The advantages of this pump format over conventional pit type pumps are:

- Quick mobilization and demobilization with minimum labour requirements

- The pump delivery hose is positioned in place with the wet-end

- The bulk of the pump unit remains clear of mining operations

- Eliminates the need for Pump Crew to work in the pit near the Highwall

- Access to water accumulating in a pit being developed by dragline operation is achieved without hindering the operation

- Able to operate and be serviced in all weather conditions

- Pump Capacity of 40L/sec @ 100m TDH

Water Pump

| Pump | Hyd Driven - Single Stage End Suction Centrifugal. Stainless Steel Impeller. |

| Suction | Fabricated screened suction - footvalve not fitted |

| Drive | 90cc fixed displacement axial piston motor |

| Speed | Max 2200 R/M |

| Arrangement | Motor drives pump shaft through a coupling supported by tapered roller bearings in a sealed housing. Bearings lubed by case oil. Mechanical seal prevents leakage. |

| Pump Performance | Rated 40 L/s @ 100m head. Unworn pump, clean water. |

| Pump Curve | No 2400-1 calculated 05/01/95 |

Wetend Positioning Support

| Wheels | 2 x 750 x 16” wheels fitted to 1550mm x 40mm axle are mounted across the wet-end, and assist in positioning the wet-end during lifting or lowering. |

| Support bracket | Hydraulically (ram) operated, acts as support for the wet-end during travelling, and hose positioning during lowering. |

Water Conduit

| Length / Type | . of 140 O.D. Pn10. Special medium density polyethylene pipe. |

Hose Reel

| Size | 2000 f drum. 2500 f rim. 100m capacity when fully layered |

| Construction | 6-65x35x3 R.H.S spokes each side welded to hub flange and rim. 6-65x35x3 R.H.S. spokes rim to drum each side. 3mm M.S. plate on drum |

| Reel Method of Support | Hydraulic Gland and Water Discharge Gland |

| Water Discharge | 150NB table 'E' flange, approx. 300mm of ground. 40NB Ball valve fitted. |

Main Frame Type

Heavy skid base – fully weld fabricated unit construction comprised of UB side runners (with wear plate). HeavyR.H.S. cross pieces, supporting the R.H.S. reel mounting frame and, fixed R.H.S extension. Heavy front tube with push pads, engine mounting, engine canopy, front bars for engine protection, fuel tank mountings, oil reservoir mountings, safety mesh mountings, and tow chain.

| Dimension | Overall – 10120mm x 2350mm x 3225mm Ground contact 4650mm x 2159mm. Mainframe 5700 x 1900. |

| Dry Weight | 8.5 tonne |

| Skid Runners | 31O UB 46 fitted with 16mm Bisalloy 500. |

| Jib Extension | 65x65x3 B.H.S and bracing 50x50x3 S.H.S |

| Push Pads | 200x100x9 R.H.S capped w/-20 ms plate |

| Engine Mounting | 150x100x10 A.I. |

| Engine Canopy | 3mm flat mild steel |

| Towing Chains | 2-3 4m long of 20mm Hercalory with 260x140x38 tow-ring link |

Hydraulic System

| Hydraulic Pump | Variable Displacement Piston Pump 100cc. Coupled to engine flywheel. |

| Operating Speed | 2000 R/M |

| Flow at Duty | 200 L/m |

| Max Pressure Rating | 280 bar. |

| Operating Pressure | 210 bar. |

| Main Relief Valve | 1" spike relief - cartridge type. |

| Auxiliary Control Valve | 4 Bank - operates lift/lower, slew, roller tilt, and pump support. |

| Reel Drive | Geroler Motor driving through a reduction gear box - Hydraulic Brake Final Drive 5:1 Chain Reduction. |

| Load Check Valve | Over run protection on reel |

| High Pressure Hose System | 1"dia. Multi Spiral high pressure. |

| Return Line | 11/4"f. Double Braid low pressure. |

| Hoses-Auxiliary System | ½"f. Double Braid medium pressure. |

| Reservoir | 360L mild steel fabricated, fitted with oil outlet, oil return, filter breather, level temperature sight glass, high and low level oil protection, drain outlet. |

| Auxiliary Hyd Reservoir | 100Lts Auxiliary tank fitted to main frame, pumped into main reservoir via the hydraulic filters, and incorporating a 12v transfer pump. |

| Return Line Filter | 1¼" dual element cartridge type. Watchdog pressure gauge fitted |

| Oil | Mineral Oil of ISO viscosity grade 22 |

Power Unit

| Engine | Cummins 6BT 5.9. Turbo charged, 6cyl 87kW continuos |

| Electrical/Watchdog | 12V Electric’s, 2 work lights fitted, battery isolator fitted.Protection on engine oil pressure, radiator level, engine temperature, high and low levels of hydraulic oil, high and low hydraulic pressure. Shut down also on hydraulic filter pressure and pump suction ball valve position. |

| Fuel Cell | Unit construction with oil reservoir, 980Lts capacity with Wiggins fittings. Weld fabricated mild steel mounted across main frame between engine and reel support frame. Drain plug fitted. Sand blasted internally. |

| Fuel Lines | 10mm SWB hydraulic hose on supply line. 10mm LP hydraulic hose return line. |

| Fuel Consumption | 24L/hour @ 2000RPM |

Painting

All frame work blasted to A.S. class 2½, primed and painted Interfine 629 White.

Functions

| Engine at 1000RPM to 1200 RPM | Auxiliary control valve functions. 4 functions - Wet-end lift/ lower Roller Plate Slew for aligning the hose to reel during reclaim Roller Plate traverse for assisting hose and wet-end entry to pit Wet-End Support Bracket supports wet-end and guides hose on initial wall contact |

| Engine up to 2000 RPM | Operation of pump function. |

The foregoing specification is correct at time of publication however, LEGRA reserve the right to amend the specification as required in keeping with market development.

- Additional fire extinguisher

- Stauff Clamps – every 450mm (NSW requirement)

- Supply and fit duel canister fire suppression

- All stainless wetted parts

- Engine oil reservoir, includes electric pump and plumbing

- Multi-flo “Hydrau-flo” positive fuel shut-off – stops pressuring of fuel tank

- Stainless Steel J Boxes – plastic is standard supply

- Stainless Steel J Boxes – plastic is standard supply

- Cat batteries, lid and box – larger box to accommodate cat batteries

- Cat Lights

- Cat Lights

- Jump start receptacle and wiring – at battery box

- Starter Battery isolator, tags, and wiring

- MDG 15 wiring

- Exhaust Heat shields (blankets) – covers exhaust and turbo, protects from burns

- SS labelling and plaques – trepholite is standard

- Dual Discharges

- 2 x Bauer Couplings

- Extendable safety barriers SWING TYPE– extend to 1.5m from frame

- 3 step walkway / Platform – allows access to jib for viewing down highwall (certified)

- Platform on outlet side of frame – allows access to the reel area for service

- Platform on outlet side of frame – allows access to the reel area for service

- Extended Push Pad on front – selected by some where curved dozer blades are used

- Channel welded to top pipe on push bar – for pushing on bar

- Bolt on sub frame with wear plate – 200 UC. Raises pump height and clearance, allows for replacement skids to be fitted independent of machine

- Horizontal exhaust on top of Canopy

- Radiator Step

- Radiator Step

- Additional hand rail on radiator and at Hydraulic Pump

- Hydraulic Pump Guard

- Hydraulic Pump Guard

- Camera on Jib – for viewing down Highwall

- Camera on Jib – for viewing down Highwall

- Whip Check on Pressure Lines

Booster Pump Options (Suits Booster Pumps Only)

- Individual speed control on Booster and Primary Pump

- Dual discharges for Booster Pump

- Dual discharges for Booster Pump

- Booster pump pipe protector (as supplied to Goonyella)

- Heat exchanger guard